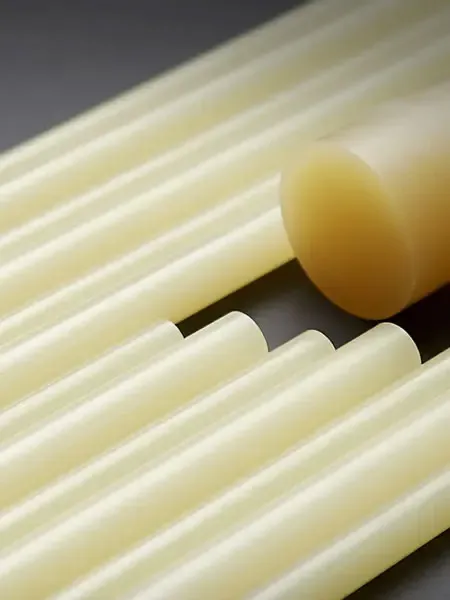

The world’s first fully certified range of

biodegradable hot melt adhesives*

Eco-conscious alternative

With options formulated using bio-based materials, all Tecbond biodegradable adhesives break down after use with no harmful effects to nature.

Fast application & setting time

Based on our best-selling packaging grades, Tecbond biodegradable adhesives give you the ability to seal more cartons in less time, speeding up the manufacturing process.

Non-toxic & solvent free

The adhesives are free from any harmful solvents or chemicals, making them safe to handle and use.

For use on carton & board

Bonds a wide range of uncoated cardboard and paper substrates, including wrap-around cartons and POS display boxes.

The world’s first biodegradable shaped hot melt adhesive

Eco-conscious alternative

With options formulated using bio-based materials, all Tecbond biodegradable adhesives break down after use with no harmful effects to nature.

Fast application & setting time

Based on our best-selling packaging grades, Tecbond biodegradable adhesives give you the ability to seal more cartons in less time, speeding up the manufacturing process.

Non-toxic & solvent free

The adhesive is free from any harmful solvents or chemicals, making it safe to handle and use.

For use on carton & board

Bonds a wide range of uncoated cardboard and paper substrates, including wrap-around cartons and POS display boxes.

Tecbond 214B & 110B-PR specs

Tecbond 214B |

Tecbond 110B-PR |

|

| Form | Shaped and bulk | Bulk |

| Open time | 10 seconds | 10 seconds |

| Viscosity / cPs | 4200 | 850* |

| Substrates | Carton and board | Carton and board |

| USP | 45% Bio-based | Can run at lower temperatures |

| Application temperature | 180°C | 180°C* |

| Learn more | Learn more |

*Refer to TDS for additional information on viscosity and application temperatures

Using hot melt adhesives for packaging applications

Unlike other carton closing systems such as tape or staples, hot melt adhesives are faster, more cost-effective, and, most importantly, non-destructive. Click below to find out more about how our adhesives can change your packaging applications.

Using hot melt adhesives for packaging applications

Unlike other carton closing systems such as tape or staples, hot melt adhesives are faster, more cost-effective, and, most importantly, non-destructive. Click below to find out more about how our adhesives can change your packaging applications.

How do Tecbond biodegradable adhesives break down?

UV light, oxygen and heat get things started

Material is consumed by micro-organisms*

Naturally occurring environmental conditions required

Leaves behind no harmful products

*Tecbond biodegradable adhesives are certified to ASTM D6400, EN13432, ASTM D6954 and ASTM D6866 (Tecbond 214B only) standard.

How does Tecbond 214B break down?

UV light, oxygen and heat get things started

Material is consumed by micro-organisms*

Naturally occurring environmental conditions required

Leaves behind no harmful products

Storage & Application of Tecbond biodegradable adhesives

Storage & Application of Tecbond 214B

Tec hot melt applicators

To get the most out of Tecbond 214B, we recommend pairing it with our range of Tec glue guns. As the only manufacturer that offers a full hot melt adhesive system, both adhesives and applicators are developed in partnership with each other to deliver optimal results and the best possible performance for the user.

Frequently asked questions

We recommend not using Tecbond biodegradable hot melts beyond 24 months from the date of manufacture.

Become a distributor

We’re always on the lookout for motivated, knowledgeable distribution companies that we can build long-lasting partnerships with. If you think your customers could benefit from any of the products in our range, get in touch now to find out more about how we can work together.

Buying smaller quantities

Power Adhesives’ range of products is available in most parts of the world via our network of specialist distribution partners.

If you’d like to make a purchase, let us know your requirements using the form to the right and we will pass your information on to one of our partners, who will be able to help you.